Reverse Osmosis

February 7, 2019

Maple sap is basically water. The clear liquid drips out of the tree drop-by-drop and has only a tiny bit of sugar in it. It can be measured with a refractometer and the sugar content is generally only about 2%. It gets to be syrup by removing most of the water, traditionally by boiling (see How Syrup is Made). The ratio is generally 40 to 1. Boil away 39 gallons of water to get 1 gallon of syrup. That's a lot of boiling, wood, steam, and time.

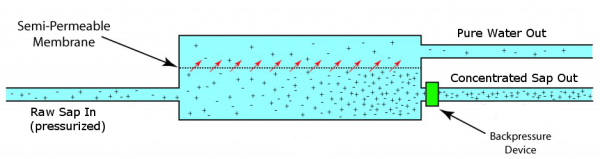

Reverse osmosis is another method of removing water. Typically used for filtering out contaminants to get pure water, reverse osmosis can separate the maple sap into pure water and (more concentrated) sap. Using this method, sap with 2% sugar can be easily concentrated to 4% sugar in one pass through the dual-outlet filters. Since that is twice as much sugar to start with, boil time could be cut in half. The percentage of sugar in syrup is around 66%, so that is still a lot of boiling, which also helps carmelize the sugars and flavor the syrup.

As I write this, I am filtering 60 gallons of sap and should wake up to 30 gallons of more concentrated sap, and 30 gallons of pure water, and will able to produce 1.5 gallons of syrup in half the time I used to. Boiling is always the most time-consuming and labor-intensive part of the process. It still will be, but now greatly reduced.

Stay tuned!